25 Ton Overhead Crane for Conveyor Manufacture Factory Australia

25 ton double girder overhead crane for sale Australia for conveyor equipment manufacturing factory. 25 ton overhead crane for sale Australia, good crane price and meet all your needs and related Australian regulations.

Our Australian customer is a professional conveyor manufacturer with a history dating back to 1880. As a benchmark in the industry, it designs and manufactures conveyors for mines, ports and other large bulk material processing plants. It is the world's largest manufacturer of high-quality conveyors and an industry leader. Factories are located in Australia, Canada, the United States, Chile, Brazil and other countries.

25 ton double girder overhead crane for sale Australia

As for the 25 ton overhead crane projects, the initial parts is very efficient. Since the crane parameters sent by the customer are very complete, clear and detailed, the crane price is quickly delivered to the Australian customer after the some detail confirmation and trial adjustment.

- Type: QDX type European double girder overhead crane

- Lifting capacity of overhead crane : 25 ton

- Lifting height of overhead crane: 5m

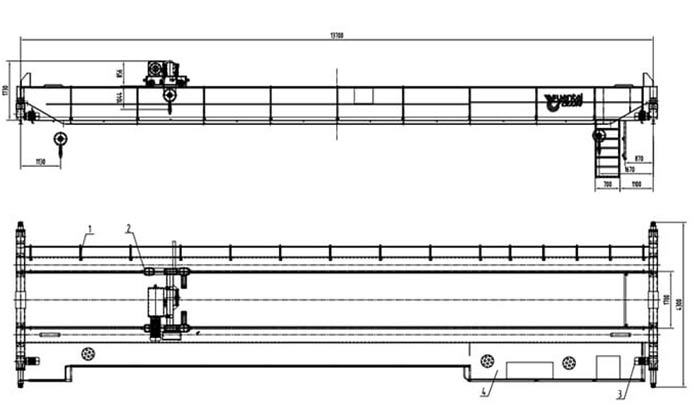

- Span of overhead crane: 13.7m

- Power supply of overhead crane: 415V/50Hz/3 Phase

The European type double girder overhead crane is a new type of overhead travelling crane,produced based on the FEM standard, with professional design, structure optimization, and meeting the requirements for strength, rigidity, and stability.EOTCRANEKIT considers the ease of manufacture, inspection, transportation, installation, and maintenance during the design process.

Light self-weight and compact structure enables the EOT crane be used in warehouse with lower room height which will greatly reduce warehouse building costs, as well as offering more space for higher hook patch, allowing you to take full advantage of the warehouse.

25 ton overhead crane drawing

Why to choose European style double girder crane:

Lightweight and modular design:

- The overall height is 20% to 25% lower than traditional cranes.

- Self-weight has been reduced by 20% to 30%.

- The maximum wheel load is reduced by 15% to 20%.

- A smaller limiting size broadens the working range.

- The use of a light structure lowers the cost of workshops.

- Low energy consumption and no upkeep.

- Every component is designed to be interchangeable and part of a standard series.

- The standard modular design ensures high quality, easy transportation, and quick delivery.

Advanced manufacturing technology:

- Pretreatment with sandblasting on steel plates results in a surface quality of Sa2.5.

- The CNC cutting machine cuts webs plate to ensure a smooth and accurate curved surface.

- Seams are soldered using automatic arc welding and are detected using ultrasonic and X-ray technology.

- To ensure flatness, the girder and trolley structure is manufactured on a floor-type boring lathe.

High Reliability:

- Use an imported motor with an insulation grade of F and an IP54 protection rating. The motor is protected by a heat-dissipating aluminum alloy stretching cover.

- Reducer imported from Germany. Hardened gears with high bearing capacity and an excellent seal that prevents grease penetration.

- The main electric components are imported from international brands such as Siemens, Schneider, and others, and have a protection degree of not less than IP54.

- The wheels are made of 65mn alloy steel, which is wear-resistant, anti-fatigue, and has a long service life.

- Its all-in-one transmission mechanism allows it to work more efficiently.

- Variable frequency control with a high and low rotating speed ratio of 1:10 increases work efficiency by more than 20%.

Question of Australian customers

"My question is related to understanding of the your experience in dealing with Australian requirements.

We want to be sure:

- that you understand this requirements

- Check what is your experience fulfilling these requirements.

- be sure that all documents and works related to the fulfilment of this requirement is part of the quote

In regards of (2) It will be great if you could get recommendations of Australian buyers that dealt with your company before.

Is it possible that we can contact any of your previous customers in Australia."

What we do to build trust?

In order to build trust between us, we have offered the following information and document to our clients.

- If you are very concerned about the quality of our 25 ton overhead crane, we are very happy you can find a third-party company to visit our factory and test our overhead travelling crane.

- The performance list of our previous Australian customer are presented for references.

- Contact our cooperating customers in Australia to let the new client to be assured about our crane quality .

Win 25 ton overhead crane projects

"We are glad to inform you that your company was choose for the supply of the 25 ton overhead crane.

Please start immediately the works on this project"

Useful information for export to Australia

- For the overhead travelling crane over 10 ton it's a must to register to the government authority before you install the crane and the authority will l come o your workshop to check.

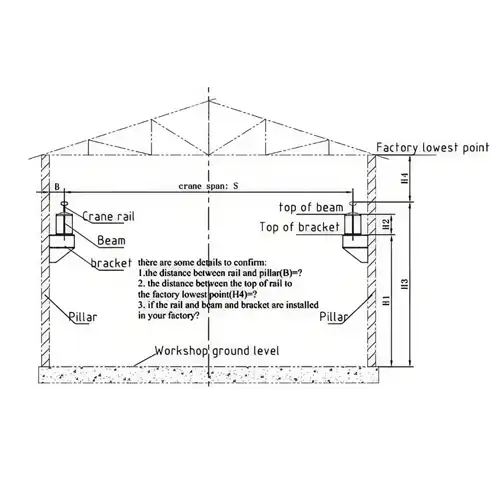

- about the shipping way, usually or the main gilders more tan 12m span, the main girder of the overhead crane needed to be cut into sections to fill into the container. And in Australia, if the main girder is cut, the welding parts needs to be inspected by the government authority, which is not preferred by most of the customer therefore, we will have to ship on bulk ship.

- As for crane register, the following information is needed such as, calculation sheet, electric drawings, and other related document. If you have any trouble about this , please feel free to contact us. We have plenty of experiences to export overhead travelling crane to Australia.

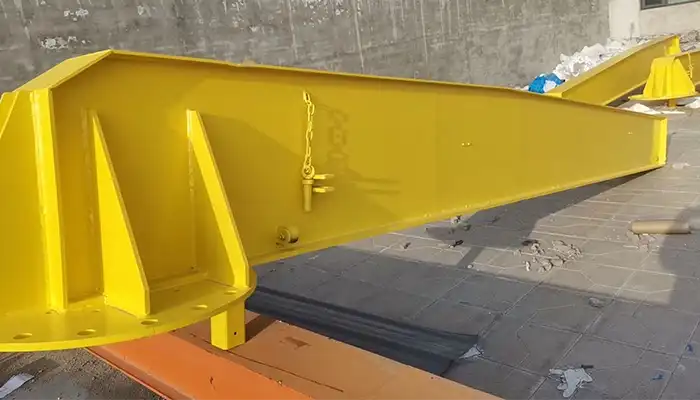

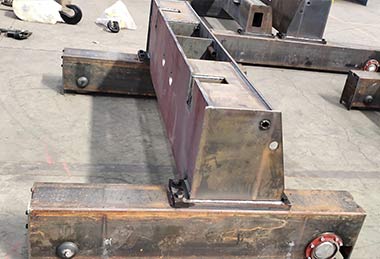

Production of 25 ton overhead crane

25 ton crane end carriages - Parts and components of 25 ton overhead crane

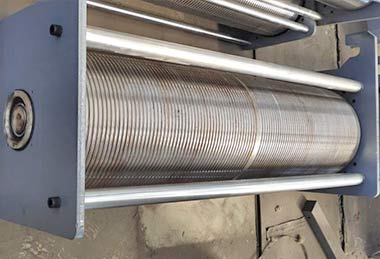

25 ton crane wire rope drum - Parts and components of 25 ton overhead crane

25 ton crane main girder - Parts and components of 25 ton overhead crane

25 ton crane end girders - Parts and components of 25 ton overhead crane

Factroy Acceptance Test of 25 ton overhead crane

FAT is the abbreviation of FACTORY ACCEPTANCE TEST. FAT includes specified system function tests, stability tests, and usability tests. FAT is carried out according to the time determined by both parties at the design liaison meeting.

- 1. In FAT, the seller shall provide necessary equipment for inspection, maintenance, measurement, test and recording.

- 2. During FAT, the seller shall provide all site facilities and simulated on-site environment.

- 3. The seller is responsible for the installation and debugging of the system.

- 4. Both buyers and sellers should send experienced engineers to participate in FAT.

25 ton double girder overhead crane testing before leaving crane factory

25 ton crane hook - Parts and components of 25 ton overhead crane

25 ton crane trolley- Parts and components of 25 ton overhead crane

25 ton crane loading testing - Parts and components of 25 ton overhead crane

25 ton crane load testing - Parts and components of 25 ton overhead crane

- Test Equipment of overhead crane :8M height test platform

- Test Weight of 25 ton overhead crane: 31.25T

- Test Method of25 ton overhead crane: Lifting 31.25 ton testing loads and keep 10min and then check the overhead crane appearance and camber changing

- Measurement device 25 ton overhead crane: Gradienter